Machinery has been a vital part of the US economy since the industrial revolution, but for all the advancements in technology and innovative progress, industry as a whole still has to deal with the fact that machines, from a $20 toaster to a $20 million auto assembler, will break at some point. When a simple appliance breaks, the owner usually just buys a new one. But when expensive machinery needs either routine maintenance or emergency service, the problem must be addressed as quickly as possible; lost time and production can be incredibly expensive.

For many years, scrap processers have had to deal with the downtime resulting from the maintenance and repair of their baling machines, particularly the wire-tie systems that required several hours of work in less than desirable conditions. However, L&P Wire Tie, a division of Carthage, Missouri-based wire product manufacturer Leggett & Platt, has devised a new system that will drastically reduce downtime and increase productivity.

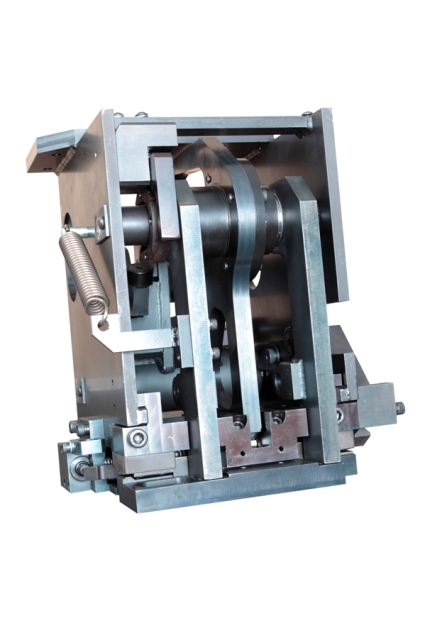

SteelOrbis talked with L&P Wire Tie President Jim York at the Institute of Scrap Recycling Industries (ISRI) conference in San Diego last week, where the company unveiled their Pinnacle Wire-Tie System, featuring the industry's first removable tying module. Over 80 percent of the tying system's movable parts (those that need regular service the most) are housed in a core that can be removed from the baling operation to be fixed and replaced with a new core, getting operations back on line in minutes.

"In many instances, the market has come to accept downtime of the entire system while the wire-tie component is repaired," said Mr. York. "It's not acceptable anymore with the availability of a product that directly improves the efficiency and productivity of the recycling center. Compromising performance should not be an option."

In addition to improving efficiency, the new system is also adaptable, and older baling operations can be retrofitted with the new device. For recycling companies that deal with various materials such as metal, plastic and paper, the Pinnacle system offers the option of "downgauging" wire; matching wire gauge to a recycled material's need can save companies from using more expensive gauges when they're not needed.

Mr. York expects that the elimination of costly downtime will improve the production of scrap baling by about 20 percent. The faster a scrap supplier can package and deliver scrap, the more supply will be available to those who depend on scrap for raw materials, such as steel mills. How this will affect the scrap market as a whole remains to be seen, but efficiency and increased productivity at any level of the steelmaking chain will undoubtedly bring positive results.

The Pinnacle System has been in development for two years, and the idea was conceived during brainstorming sessions with customers to discover their biggest concerns and find ways to address them. Full production of the modules should start in mid-summer, and according to Mr. York, there is already an overwhelming positive response.

"There's a long line of customers waiting to get a hold of this product," Mr. York said. "Once production gets rolling and they're out there in the industry, I think it's going to change the way people think about scrap baling."